Polycarbonate Rods and Sheets Manufacturer

Polycarbonate Rods and Sheets provide high dimensional stability and optical clarity. It offers exceptional electrical and thermal resistance. It can be moulded and is simple to process, weld, and bond. Polycarbonate rods are resistant to most inorganic chemicals, lubricants, and dilute acids/alkalis. It also has excellent weather resistance and can be UV stabilised for increased ozone resistance.

Extruded Polycarbonate Clear Rod and sheet is a high-performance, amorphous thermoplastic with superior dimensional stability, low moisture absorption, and rigidity. The long-term service temperature range for Polycarbonate Engineering Grade Rod is -40°C to 115°C, with a short-term maximum service temperature of 140°C.

Typical applications for Polycarbonate Engineering Grade Rod & Sheet include the electrical and electronic sectors, safety engineering, and vehicle construction. Polycarbonate Engineering Grade Rod is a material ideal for billeting, precise grinding, and CNC turning.

NOTE: Engineering Grade Polycarbonate ( PC ) is not optically clear and should be chosen for its technical and mechanical features rather than its aesthetic qualities.

We offer similar materials such as Acrylic Cast Clear Rod and Acetal C Extruded Natural Rod. If you require machined or finished Polycarbonate Engineering Grade components, please contact our team for more information.

- Amorphous

- Thermoplastic

- Exceptional high impact strength over wide temperature range

- Excellent combo of toughness, heat and flame resistant, and dimensional stability

- Excellent impact resistance

- Continuous use of temperature to 290° F (145°C)

- Excellent thermal performance

- Good dielectric properties

- Good mechanical and electrical properties

- FDA Compliant

- Resists acids

- Low moisture absorption rate

- Good transparency

|

MECHANICAL PROPERTIES |

VALUE | UNIT | PARAMETER |

NORM |

|

Tensile strength |

69 | MPa | 50mm/min |

DIN EN ISO 527-2 |

|

Tensile strength at yield |

69 | MPa | 50mm/min | DIN EN ISO 527-2 |

| Elongation at yield | 6 | % | 50mm/min |

DIN EN ISO 527-2 |

|

Elongation at break |

90 | % | 50mm/min |

DIN EN ISO 527-2 |

|

Flexural strength |

97 | MPa | 2 mm/min, 10 N | DIN EN ISO 178 |

|

Modulus of elasticity (flexural test) |

2300 | MPa | 2 mm/min, 10 N |

DIN EN ISO 178 |

|

Compression strength |

16/29/64 | MPa | 1 % / 2 % / 5% |

EN ISO 604 |

|

Compression modulus |

2000 | MPa | 5mm/min, 10 N |

EN ISO 604 |

|

Impact strength (Charpy) |

n.b. | kJ/m2 | Max. 7,5J | DIN EN ISO 179-1eU |

| Notched impact strength (Charpy) | 14 | kJ/m2 | Max. 7,5J |

DIN EN ISO 179-1eA |

|

Ball indentation hardness |

128 | MPa | ISO 2039-1 | |

| Modulus of elasticity | 2200 | MPa | 1 mm/min |

DIN EN ISO 527-2 |

Applications

Designed for machined and fabricated components

Key Features

- Temperature: -40°C to +115°C (+140°C short term).

- Rich in optical properties

- Truly chemical and Ozone resistant

- Easily welded, bonded, and machined

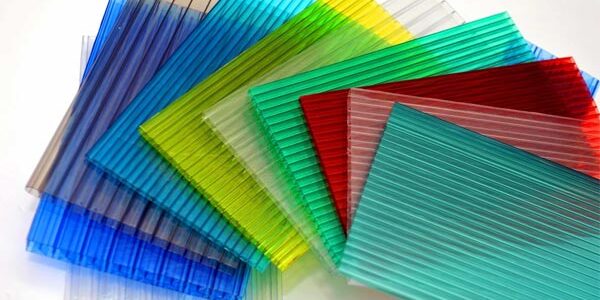

Polycarbonate Sheets

Polycarbonate Sheets are lightweight, virtually unbreakable, and offer excellent clarity. Ideal for roofing, glazing, machine guards, and safety enclosures. They are UV protected and can withstand high impacts without cracking. These sheets are known for their durability and transparency, making them a preferred choice in both industrial and residential applications. Whether used indoors or outdoors, polycarbonate sheets ensure safety, longevity, and clarity without compromising on strength.

Polycarbonate Sheets Technical Information

| Property | Specification |

| Density | ~1.20 g/cm³ |

| Impact Strength | 250 times stronger than glass |

| Temperature Resistance | -40°C to 120°C |

| UV Coating | Available |

| Transparency | ~90% light transmission |